Application

CY-JP20kn Microcomputer-inodzorwa Inonyora Spring Situble Muchina unonyanya kuswededza muedzo wakasiyana-siyana Special fixtures inogona zvakare kuitwa kuti ienderane neyekuneta bvunzo yemhando dzinokosha.

Iyo microcomputer-inodzorwa inotsoropodza chitubu chekuyedza muchina wakakwira, high-programs Tech nzira.

Zvinyorwa

| Zita | kutaurwa | ||

| 1 | Maximum Test Force | 20kn | |

| 2 | Nhamba yeChiteshi chebvunzo | 1 | |

| 3 | Bvunzo frequency | 0.5 ~ 5Hz | |

| 4 | Frequency kuratidza chokwadi | 0.1 HZ | |

| 5 | Edza AMPLitude | ± 50mm | |

| 7 | Maximum Kugona kweChinyorwa | 1 bhiriyoni nguva | |

| 8 | Kuverenga STMS ECHECKE | ± 1 | |

| 9 | Maximum Outer Diameter yeyedzo chidimbu | Φ90mm | |

| 12 | Magetsi Supply Voltage (matatu-Wire ina-Phase System) | 380VAc 50hz | |

| 13 | Main mota simba | 7.5kw | |

| 14 | Saizi | Host | 1200 * 800 * 2100 (h) |

| Dzora Bhokisi | 700 * 650 * 1450 | ||

| 15 | Uremu | 450kg | |

ZVINOKOSHA ZVINOKOSHA

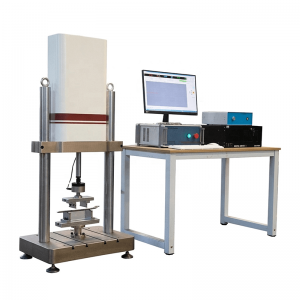

1.1 host:Iyo host inonyanya kuumbwa nechimiro, muchina wekuisa muchina wekutakura, muchina wekutapurirana, uye chidimbu. Chimiro chakaumbwa nekhimendi, webasa, chikuva, chinja chinhambwe, chikwama chinosimudza mashini, chigadziko uye zvimwe zvikamu. Iyo ikholamu, workbench, chikuva, chinja chinhambwe, uye chikwama chinosimudza mechnism chakaiswa pamwe chete uye zvakaiswa zvakaiswa pachigadziko; Iyo yakaedzwa yekuvhunduka inotora yakaiswa pakati pepafura yekunakisa uye inotungamira screw, uye chidimbu chebvunzo cheshuwa chinogona kusangana neshure kweiyo tungamira iyo fixture. Zvinodiwa.

1.2 Kuisa michina:Icho chimiro chechimiro, chinonyanya kuumbwa nekrank inobatanidza iyo tsvimbo mechanism, iyo inoshandura iyo inotenderera yemotokari mukutenderera mumutsara wekudzokorora kufamba; Nekugadzirisa iyo eccentricity yeiyo inotsvedza, iyo linear inodzokorora kufamba kwekufamba kunogona kugadziridzwa kune iyo bvunzo strokedhi inodiwa neyebvunzo chikamu.

1.3 Transmit System:Iyo yekufambisa michina inoumbwa neyakaenzana-chikamu asynchronous mota uye flywheel. Kumhanya kwemota kunogona kugadziriswa neye frequency converter, kuitira kuti iyo bvunzo frequency inogona kuve yakagadziriswa inogadziriswa mukati megumi negumi ne5 HZ.

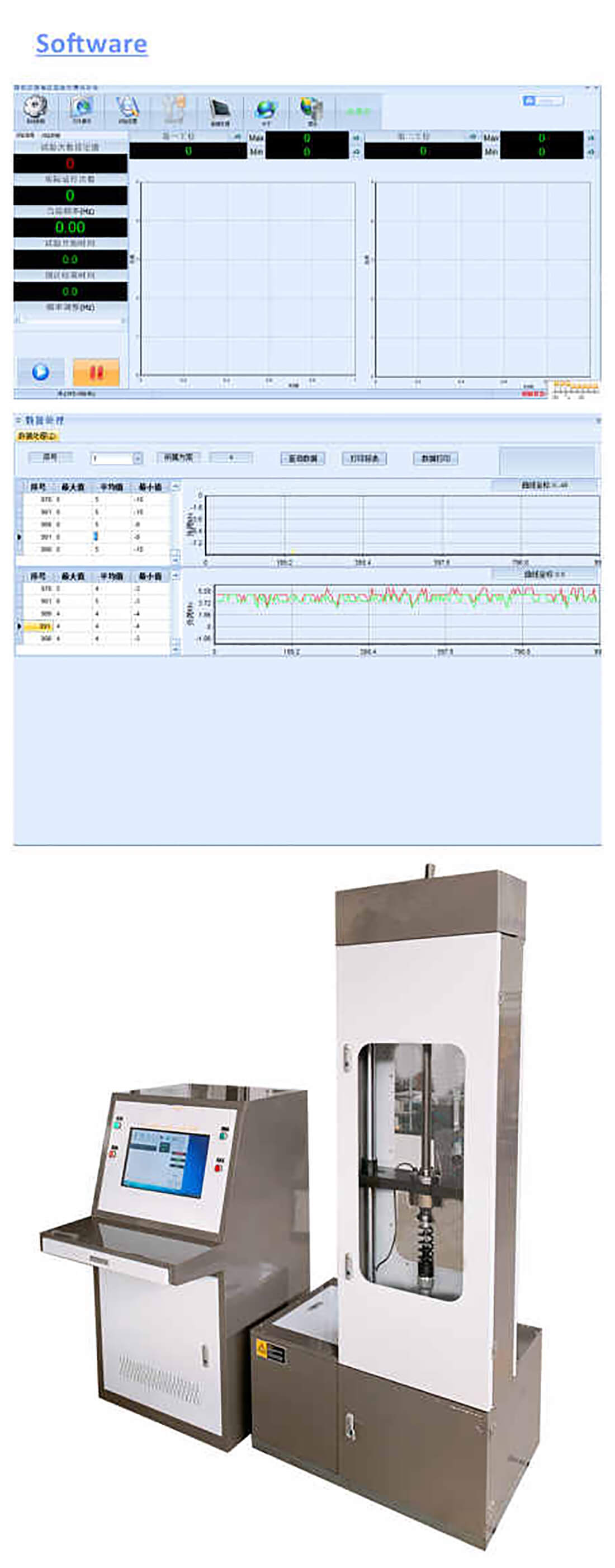

1.4 Control System:Kuyera komputa uye kudzora system yakazvimirira yakagadzirwa uye inogadzirwa nekambani yedu. Iyo ine basa rekurangarira, iro nderekuti, nhoroondo yeyedzo yeyedzo inogona kuwanikwa chero nguva. Iyo kuyerwa uye kudzora system ndiyo nzvimbo yeiyo bvunzo mudziyo. Kune rimwe divi, komputa inounganidza muedzo wekuyedza chiratidzo chekushamisika kwega kwega, uye kuratidza mamiriro ezvinhu akasiyana-siyana , Edza kumanikidza kukwikwidza, etc. Kune rimwe divi, maratidziro ekudzora anofanirwa kuiswa maererano neyekudzora nhamba anotumira chiratidzo chekudzora, uye akasimba anodzora mari inogadzirisa nzvimbo yepamusoro uye inodzora nzvimbo yekugadzirisa nguva, inodzivirira zviito zvisina kunaka panguva yekuedzwa, uye inodzivirira inoshanda uye michina Kuchengetedzwa, sezvakaratidzwa mumufananidzo:

1.5 Software Basa Rekusuma

1.5.1 Kuwanda kwemiedzo kunogona kuiswa. Iyo huwandu hwepamoyo hwezvenguva yekugona ndeye 1 bhiriyoni nguva.

1.5.2 Nhamba yemiedzo inosvika kune iyo nhamba yeSet, uye muchina weyedzo unodzorwa kumisa bvunzo.

1.5.3 Muedzo weSoftware Software Inoratidza iyo bvunzo frequency uye nhamba yemuedzo kuburikidza nekombuta uye vatongi kuzorora uye kuvhara.

1..

1.5.5 Ine chaiyo-nguva yekuratidzira basa rekuyedza simba-nguva curve yekuvhunduka kwesimba

1.6 Zvinhu zvakakura zviri seanotevera:

1.6.1 Iyo yakakwira uye frequency inogona kugadziriswa zvakasununguka.

1.6.2 Digital kuratidzwa kwehuwandu hwehuwandu uye frequency.

1.6.3 otomatiki shutdown yePreset bvunzo nguva, kunyatsoita.

1.6.4 Muedzo weimwe kaviri yekuvhundutsa anokwanisa kuitwa, kana muedzo wezvakawanda zviviri zvekuvhundutsa leckorers inogona kuitwa.

1.6.6 Nhamba yePreset yeShutowns inogona kushandiswa bvunzo dzisina kutarisirwa;

1.6.7 Pane bvunzo yekuisa mari yekuisa mbira;

1.6.8 yakagadzirirwa nekugadziriswa kwekugadzirisa, iyo iri nyore kugadzirisa gadziriso;